What Are You Looking For?

Populnr Soarchos

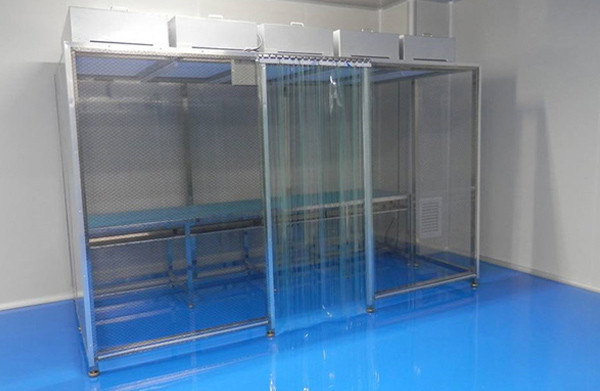

Clean shed, specifically in the high clean micro-environment of the air outlet, by the fan

1, efficient filtration unit

2. Fasteners

3. Aluminum profiles

4, support gasket 5 and support;

The clean shed support is connected to the top of the clean micro-environment space, and the top material is generally stainless steel plate, cold-rolled steel plate spray or anti-static acrylic plate; Clean shed fan 1 is fixed on the support through fastener 3, so that fan 1 can always be fixed on the top of the microenvironment after the initial installation;

The high efficiency filter unit 2 is set under the fan 1, which is closely connected with the fan 1. The high efficiency filter unit 2 can be selected according to the actual needs of different customers. In the production and development of high precision technology, for example, in the semiconductor industry, PTFE high efficiency filters with high purification level are generally used.

The high efficiency filtration unit 2 of the clean shed is supported by an aluminum profile 4 fixed on the bracket and a support gasket 5, which can be removed. The clean microenvironment can be set to different sizes, heights and materials according to actual needs.

The horizontal cross-sectional area of fan 1 and efficient filtration unit 2 in the clean shed is the same to ensure that the air is reasonably and evenly blown from top to bottom into the microenvironment.

There is a small amount of space between the high efficiency filter unit 2 and the fan 1 in the clean shed, generally 10-15mm. When the high efficiency filter unit 2 needs to be replaced, the high efficiency filter unit 2 can be lifted up inside the microenvironment.

Half of the clean shed support gasket 5 can be embedded in aluminum profile 4, and the other half is extended to support the high efficiency filter unit 2. After the high efficiency filter unit 2 is lifted, the support gasket 5 used to support the bottom four sides of the high efficiency filter unit 2 can be removed. The support gasket 5 of the clean shed is usually made of aluminum structure. At this time, you can take out the high efficiency filter unit 2 and replace it.

The aluminum profile 4 of the clean shed is a special aluminum profile, and the horizontal plane of the aluminum profile has at least one groove, which can place the support gasket 5. The commonly used structure is shown in the figure, but it is not excluded that there are other similar structures with the same function. The support gasket is embedded in the aluminum profile groove while extending to support the high efficiency filter unit.

Because the high efficiency filter unit 2 is relatively high in normal use, it needs to be replaced frequently. The traditional clean microenvironment requires the operator to climb to the top of the microenvironment when replacing it, which is unsafe and inconvenient. Moreover, the load-bearing capacity of the overall structure of the microenvironment becomes higher, resulting in higher design requirements and increased costs. The utility model has the advantages that the installation is simple and fast, and the high-efficiency filter unit can be replaced in the microenvironment, which is convenient and safe; Cost savings without considering the overall load-bearing capacity of the microenvironment.

It should be emphasized that the above is a practical and better embodiment, and it is not a restriction of any form on the appearance of the utility model. Any simple modification, equivalent changes and modifications made according to the above embodiment are still within the scope of the scheme.