Product features

The clean room decoration project needs to pass GMP certification. The work includes: all the ceiling, wall, doors and Windows, transfer box installation and part of the purification equipment installation.

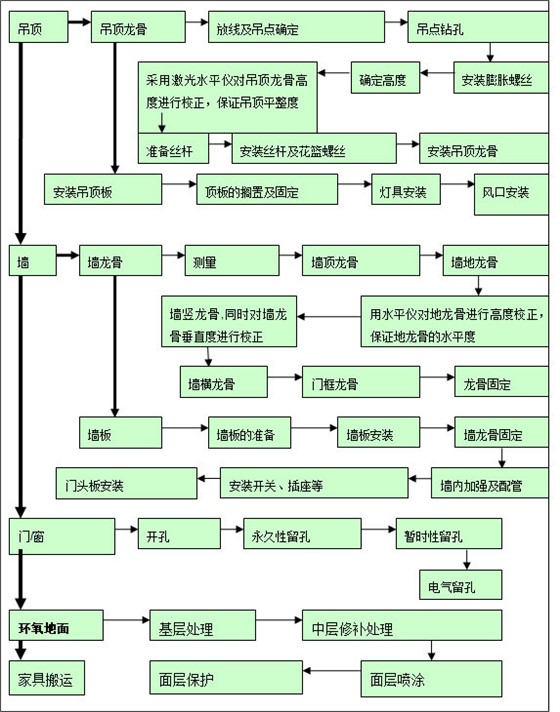

Process flow

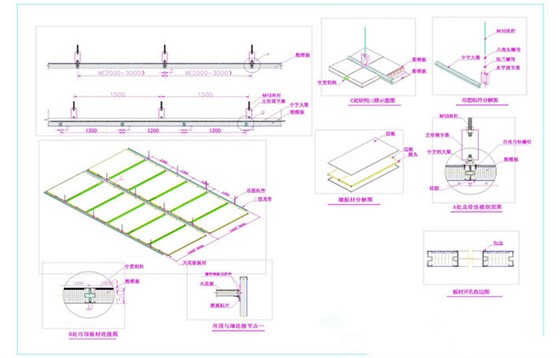

1.1.3. Color steel plate installation and construction scheme

Construction scheme

1.1.3. Color steel plate installation and construction scheme

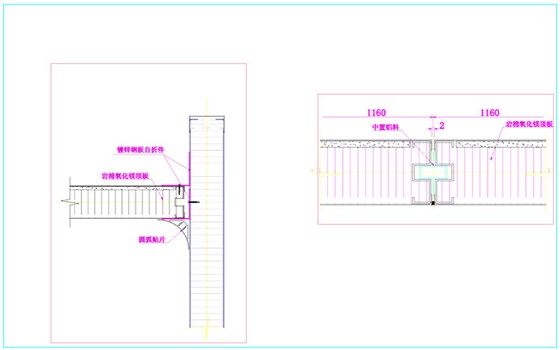

Clean room wall

1. Overview

The detachable color steel plate hollow wall surface is smooth and flat, there is no exposed keel, it is a steel structure system, and static electricity can be released from the ground through the keel. The wall panel is disassembled and can still be used after disassembly.

2. Size of the wall

Standard wall thicknesses of 60 mm, 76 mm and 100 mm can be increased or decreased to accommodate air ducts and other in-wall facilities. The gaps between the wall panels are sealed with silicone. The double wall weighs about 35kg/m2. The structure of the wall is air-tight, and when the pressure difference between the two sides of the 3-meter-high wall panel is 40Pa, the bending degree is less than 3 mm/meter. Standard walls have a fire resistance of more than 60 minutes and are certified by the Chinese fire protection Authority.

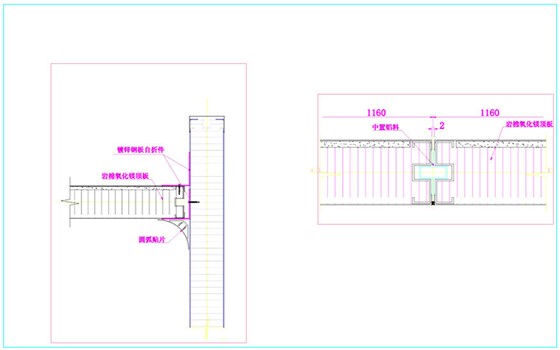

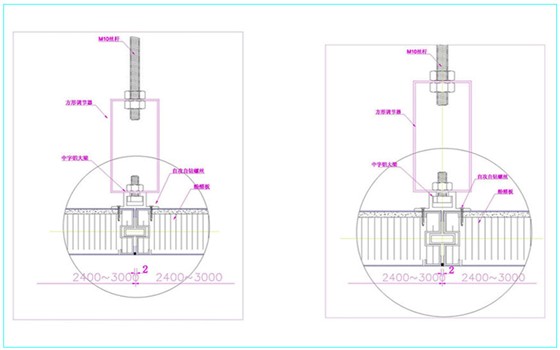

3. Aluminum keel and support

Clean room wall keel hot dip galvanized (thickness 1.2mm, galvanized thickness of 35 microns).

4. Sheet

A variety of materials can be selected according to different requirements and specifications [based on aluminum (zinc) alloy keel and support]

5. Steel plate

0.6mm polyester coated galvanized steel sheet is protected by plastic film during transportation and installation.

6. Mechanical stability

The mechanical stability of the wall meets international requirements. Additional reinforcement measures are required for loading of single wall panels exceeding 30kg per meter extension. When the pressure difference between the two sides of the wall exceeds 100Pa, strengthening measures should also be taken according to the overall structure.

Step 7 Keep warm

Heat transfer coefficient:

The heat transfer coefficient of the uninsulated wall is: 4W/m2K;

The heat transfer coefficient of rock wool insulation wall is 0.502W/m2K.

8. Building deviation

The unevenness of the ground can be eliminated by the keel, so as to ensure that the height of the suspended ceiling is in a horizontal line, and also to ensure the air tightness.

The ground keel can adjust the ground deviation of about 25mm, and special adjustment methods will be adopted when the deviation is greater than 25mm.

9. Quality standards

The installed wall system meets the following criteria:

If luminaries and filter plenum need to be installed, the keel can be pre-strengthened at the factory.

0.6mm polyester coated galvanized steel sheet is protected by plastic film during transportation and installation.

10. Quality standards

The installed wall system meets the following criteria:

-- International clean room 209E standard; The control environment can reach the cleanliness requirements of 100, 10000, 100000 and 300000 respectively.

-- ISO14644, the control environment can meet the cleanliness requirements of clean room level 5, 6, 7 and 8 in ISO.

-- EU-GMP, the control environment can meet the requirements of Class A, B, C and D respectively.

-- China GMP.