Product introduction

The building block of a cleanroom ceiling system is the connection and suspension system. The CleanSeal offers a true extruded aluminum 2″ cleanroom ceiling system. This is the most cost-efficient system for cleanroom classes from Federal Standard 209E and ISO cleanrooms. Our cleanroom ceiling t-bar grid meets class 10 to 100,000 clean room or any full coverage HEPA application. Available in polyester powder coated white or anodized clear aluminum both 3/8″ thread rod hung or wire hung. Our cleanroom gasket ceiling can meet all your cleanroom ceiling needs.

Cleanroom Ceiling Systems CleanSeal thread rod hung suspended cleanroom ceiling systems share attributes that when combined create the best cleanroom t-bar ceiling in the industry. Customizing this system to meet your specific needs is easy and worry-free. Call one of our engineers today to discuss options and the system that best meets your needs.

Cleanroom ceiling systems t-bar ceiling grid is approved equal to Gordon cleanroom grid DS-38 and is superior to Gordon cleanroom grid DS-20. When building you modular cleanroom or conventional cleanroom use the best cleanroom gasket ceiling grid on the market today.

All 2” cleanroom ceiling grid systems are suspended with 3/8″ threaded rod and turnbuckle for ultimate rigidity and precise adjustment.

The cleanroom ceiling system is often used to retrofit and convert an existing room into a cleanroom.

Product feature

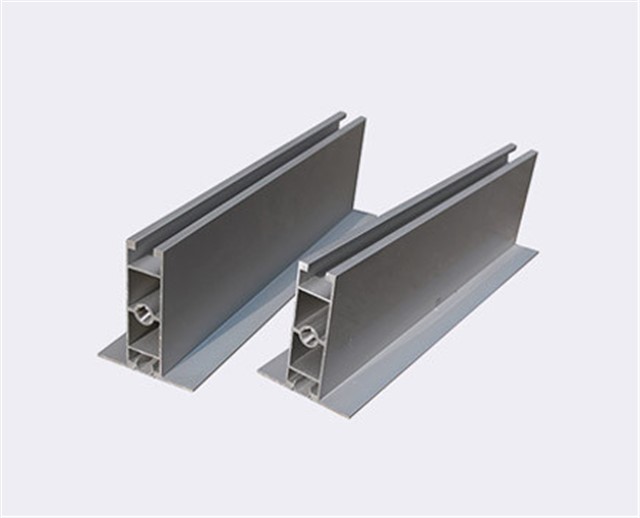

Keel arrangement

The keel is made of 6063 aluminum alloy with anodized surface.

The joint is made of aluminum-zinc alloy and formed by high pressure precision die casting.

Surface spray (silver gray).

Can easily install HEPA, FFU lamps and other equipment.

Assembly with internal and external compartments.

Integrated installation of automated conveying system.

Dust-free level upgrade or space change.

Suitable for clean room within CLASS1~10000.

Keel characteristics

The FFU keel is designed according to the characteristics of the clean workshop, and has the processing barrel, easy assembly and disassembly, which is convenient for the daily maintenance work after the clean room is completed. The modular design of the ceiling system, large plasticity, can be factory production, but also can be cut on site, processing and construction pollution is greatly reduced, and the system strength is high, can walk on it, especially suitable for high law net area, such as electronics, semiconductors, pharmaceutical lines and so on.